Industry

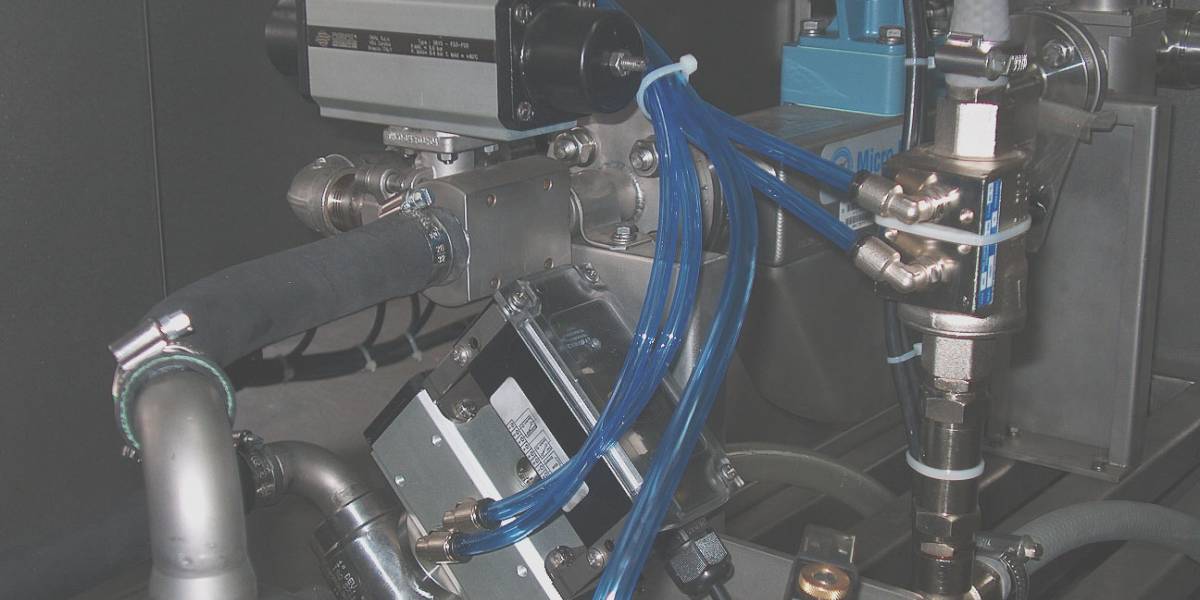

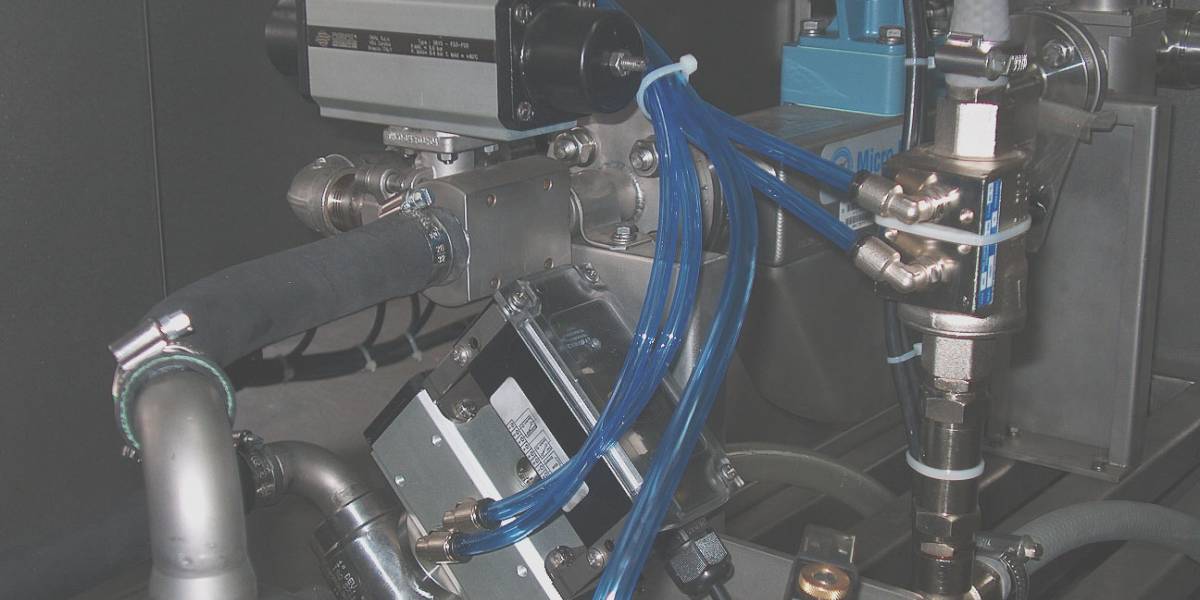

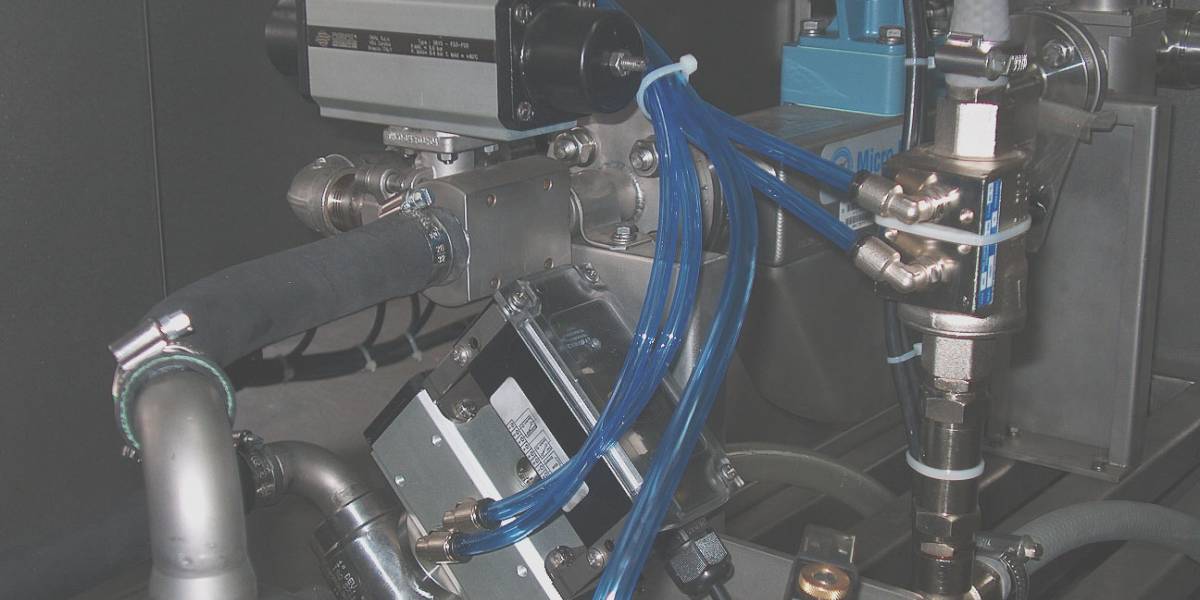

The pneumatic actuators and valves of OMAL can be adapted to the many applications of the processing industry, from vapour applications, technical gas generators, ceramics and glass production, textile and various other types of plants.

Pneumatic actuators and valves for industrial systems

Steel mills, technical gas generators, ceramics, glass and textile: our actuators are designed and produced with the "Scotch-Yoke" instead of the " Pignon and rail" system. This system offers a series of benefits: it has a higher torque drive which enables the reduction of the bulk and the size of the actuator with respect to the same automated valve. With reduced volumes there is a lower consumption of compressed air, and therefore a potential reduction of the compressor. It is moreover Maintenance-free, and does not need lubrication interventions, and optimising the internal component, it has a certified life of a million cycles. The pneumatic valves of the co-axial series called "VIP," are used mainly by constructors of OEM machines or in pneumatic distribution plants and are an authentic example of how OMAL does not produce mere "industrial components " or "commodities, " but is furnishing innovative solutions. The VIPs can in fact replace the threaded floating ball valves with pneumatic actuators, but in a more reduced volume and with -60% of air usually needed to operate with "standard valves." Moroever, the operating time is very fast (from 0.01 to 0.2 seconds, according to the dimensions) and the duration is incredibly high: about 500,000 cycles.