APPLICATIONS

The force of our products, their industrial application

OMAL supplies excellent products for industrial applications such as the food, chemical and pharmaceutical industries, power and energy, naval and many others.

OMAL supplies excellent products for industrial applications such as the food, chemical and pharmaceutical industries, power and energy, naval and many others.

Hydrogen, as a sustainable carrier, plays a key role in the energy transition. After in-depth studies and research, and thanks to the know-how developed over the years, we are able to offer a wide range of actuated valves for the entire hydrogen supply chain: from production to refueling stations, including transportation and storage.

Our H2 valve series covers a pressure range from 25 to 700 bar and includes:

|  |  |  |

| H2 INVICTUS PN700 ISO 19880-3 | KRATOS | SUPREME | THOR |

|  |  | |

| MAGNUM | ITEM 424 | ARES |

Resistance to environmental corrosion and the compact design are the strengths of the OMAL offer for the Naval and Off-Shore sectors.

Actuators for the nautical industry

The OMAL actuators in STAINLESS STEEL and aluminium with special coatings (PTFE, Nichel-coated, Zinc-plated) are examples of products suitable to the difficult conditions which the various applications in the sector may require. A further example of innovation is our actuator with integrated Handwheel “DANV” which responds to the market demands by further reducing the total bulk in the applications that also require manual control as an additional safety measure. In fact, it not only eliminates the need for two separate components (Actuator +handwheel) but is designed to avoid needing a valve connection kit, thus reducing the total bulk and every possible misalignment between the valve, reducer and actuator stem.

|  |  |  |

| MAGNUM WAFER | THOR SPILT BODY | BUTTERFLY VALVES | "EA" ELECTRIC ACTUATORS |

| |||

| AGO - ALUMINIUM PNEUMATIC ACTUATORS |

The OMAL butterfly valves can be equipped to respond to the demands of the processing sector, desalination and movement of waters.

Valves for water processing plants

The structure covered in epoxy paint in combination with washers NBR, EPDM and FKM and STAINLESS STEEL and Bronze-Aluminium discs for salt water ensure the compatibility with various chemical products and fluids. The valves' measurements are DN40 (1"1/2) to DN300 (12") for all the configurations and up to DN600 (24") for the EPDM/STAINLESS STEEL configuration. In the case of remote stations, electrical actuators are commonly used to automatize the process should a source of compressed air not be available. The OMAL EA and AE actuators are used for on-OFF applications and electrical AM Modulating actuators.

|  |  |  |

| MAGNUM WAFER | THOR SPILT BODY | BUTTERFLY VALVES | "EA" ELECTRIC ACTUATORS |

|  | ||

| AGO - ALUMINIUM PNEUMATIC ACTUATORS | AGO HANDWHEEL |

The cement and mining works are a niche sector, and OMAL guarantees efficiency and safety thanks to the production of products for safe zones, for example in the external areas of mines Ex II 2 GD.

Valves and actuators for cement factories and mines

The OMAL products for safe zones Ex II 2 GD are useful applications for the external areas of mines.

The MAGNUM (wafer and split wafer) and THOR (split body) provide for standard production of STAINLESS STEEL frames or carbon steel, ball seat in TFM1600 with the addition of an elasticised seal in graphite and a pack of V-shaped washers preloaded by a Belville washer for the shaft seal. The Valves are certified PED, ATEX, API6D, TALUFT FUGITIVE EMISSION, FIRE SAFE, DVGW, RINA and SIL3. The range is offered with matching ATEX certified pneumatic actuators, limit switch box and solenoid valves for explosive areas.

Security in these CNG, LPG Methane areas is the key factor. Hercules, Magnum Wafer and Thor valve Trunnion Supreme are produced to endure and are highly reliable.

Actuators and valves for explosive atmospheres

For the CNG, LPG, Methane and Biogas sectors OMAL offers high security valves. Our motto “Empowered Performance” is evidenced also in the quality certifications required in the sector. The valve HERCULES up to 500 bar, is made in materials developed in-house and SIL3 and ATEX certified, and is designed for the high cycles at elevated pressures. The floating ball valves MAGNUM (Wafer) and THOR (Flanged) and Trunnion-mounted SUPREME are designed according to the standard API 6D, and certified SIL3, ATEX , TA LUFT fugitive emission and Fire safe to offer security where needed. The range offers matches with our own ATEX certified pneumatic actuators, limit switch box, and solenoid valves for explosive areas. The excellent durability is a consequence of studies on construction and the fine-tuning of the production process. Reliability and safety of plants are likewise the objective and natural effect of our activities.

The pneumatic actuators and valves of OMAL can be adapted to the many applications of the processing industry, from vapour applications, technical gas generators, ceramics and glass production, textile and various other types of plants.

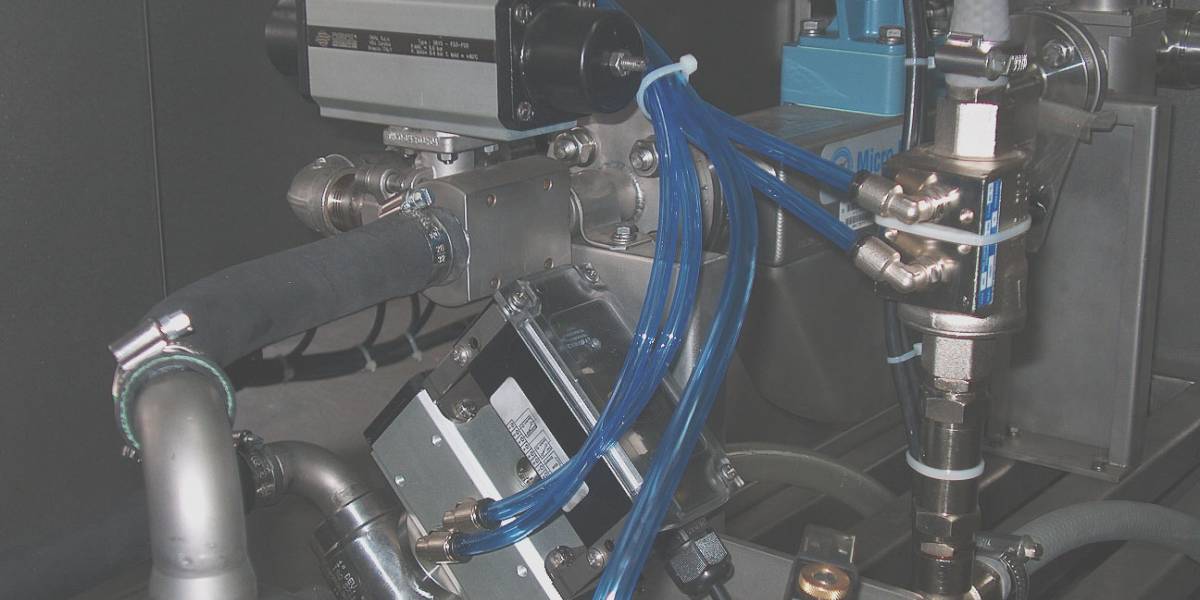

Pneumatic actuators and valves for industrial systems

Steel mills, technical gas generators, ceramics, glass and textile: our actuators are designed and produced with the "Scotch-Yoke" instead of the " Pignon and rail" system. This system offers a series of benefits: it has a higher torque drive which enables the reduction of the bulk and the size of the actuator with respect to the same automated valve. With reduced volumes there is a lower consumption of compressed air, and therefore a potential reduction of the compressor. It is moreover Maintenance-free, and does not need lubrication interventions, and optimising the internal component, it has a certified life of a million cycles. The pneumatic valves of the co-axial series called "VIP," are used mainly by constructors of OEM machines or in pneumatic distribution plants and are an authentic example of how OMAL does not produce mere "industrial components " or "commodities, " but is furnishing innovative solutions. The VIPs can in fact replace the threaded floating ball valves with pneumatic actuators, but in a more reduced volume and with -60% of air usually needed to operate with "standard valves." Moroever, the operating time is very fast (from 0.01 to 0.2 seconds, according to the dimensions) and the duration is incredibly high: about 500,000 cycles.

The application field of the industrial production of ink and paint uses chemical components and requires highly reliable and safe materials for the control of fluids .

Valves for paint production plants

The special valve seats of OMAL are developed for the control of XYLENE, TOLUENE and the solvents used in the INK & PAINT sector, and their design guarantees the cycles and reliability of the l MAGNUM and THOR ball valves. They are also perfect for all the water-based applications.

MAGNUM (wafer and split wafer) and THOR (split body) valves provide as standard constructions in stainless steel or carbon steel, ball seat in TFM1600 with the addition of an elasticized graphite seal and accompanied by a pack of V washers preloaded by Belleville washers for the shaft seal.

The Valves are PED, ATEX, API6D, TALUFT FUGITIVE EMISSION, FIRE SAFE, DVGW, RINA and SIL3 certified.

The food industry deals with raw materials, often derived from agriculture, that are transformed into consumption products in oil plants, chocolate factories and processing plants under controlled atmosphere.

The industrial processes which today perform these transformations are strict and complex. The ideal products of OMAL are the STAINLESS STEEL VALVES.

Valves for the control of food fluids

OMAL offers STAINLESS STEEL VALVES for the foods sector. For example the valves in CF8M angles with special connections among which are: Clam 3A diffused in the foods sector, Flanged ANSI 150 or NPT and ISO threads. For fluids control we suggest the butterfly VALVES in STAINLESS STEEL threaded to control the fluids and ball valves in STAINLESS STEEL whether flanged or threaded.

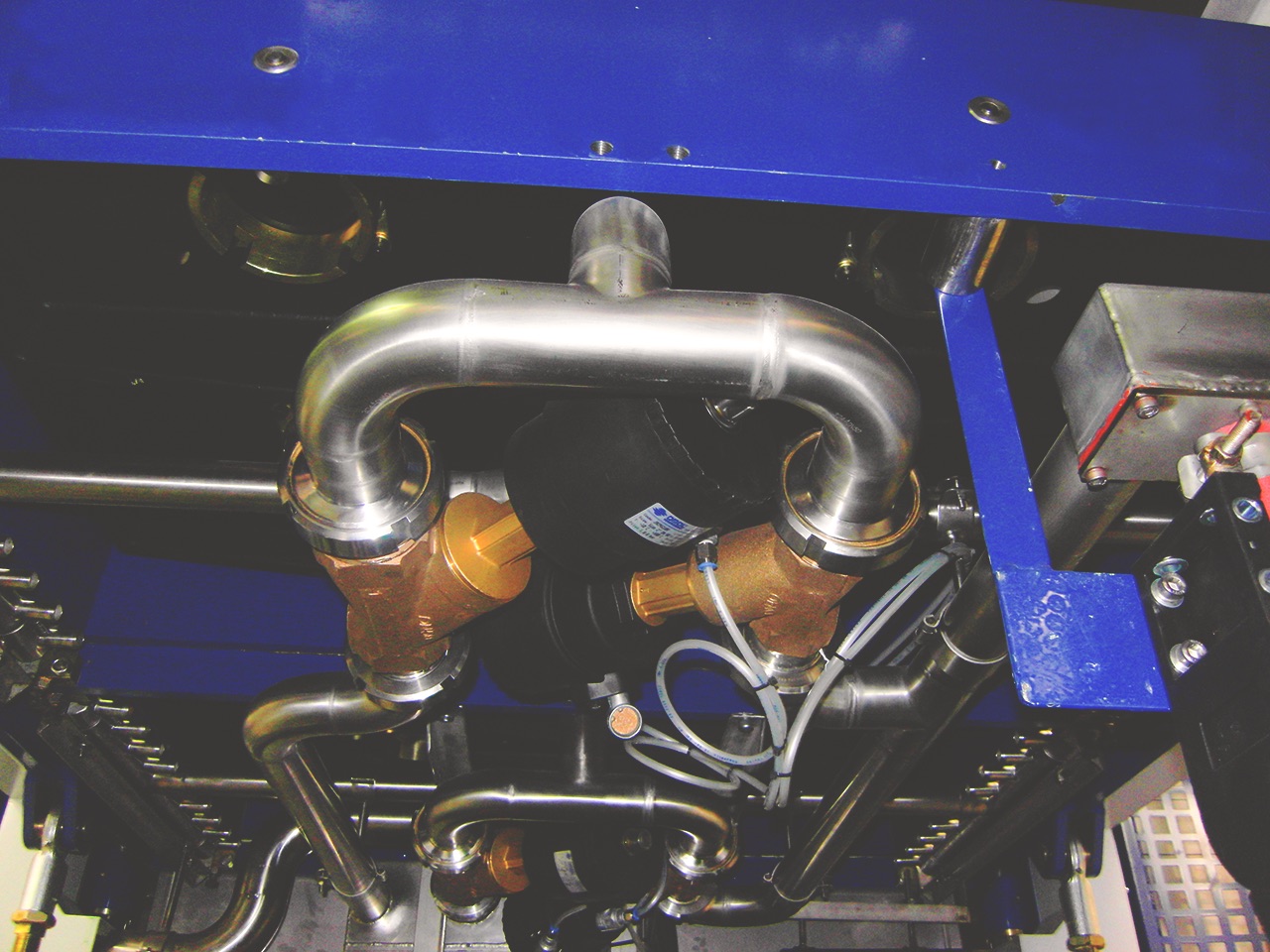

In the turbine, generator and cooling tower applications, OMAL offers the ball valves OMAL MAGNUM (wafer and split wafer) and THOR (split body).

Valves for energy systems

The specifications provide for the standard construction of frameworks in STAINLESS STEEL or carbon steel, ball seats in TFM1600 with the addition of an elasticized graphite seal and accompanied by a pack of V-shaped gaskets precharged with Belleville washers for the shaft seal. The Valves are PED, ATEX, API6D, TALUFT FUGITIVE EMISSION, FIRE SAFE, DVGW, RINA and SIL3 certified.

The cellulose and paper industry comprise companies that use wood as the raw material and produce wood paste, paper and cardboard and other cellulose-based products. The MAGNUM wafer and split wafer and THOR valves are used in this sector.

Valves for paper industry

For this application field the MAGNUM VALVES (wafer and split wafer) and THOR (split body) provide standard creations of STAINLESS STEEL or carbon steel structures, ball valve seats in TFM1600 with the addition of an elasticized graphite seal accompanied by a pack of V-shaped washer precharged with Belleville washers for the shaft seal. The Valves are PED, ATEX, API6D, TALUFT FUGITIVE EMISSION, FIRE SAFE, DVGW, RINA and SIL3 certified.

The automotive sector is a highly competitive one, due to the high levels of studies on innovative solutions that allow performance to be reached, with limited consumptions and emissions, and because of this, is subject to continual changes.

Valves for fire-fighting vehicles, component moulding and washing

OMAL produces valves also for the automotive micro sectors like Fire-Fighting Vehicles, Moulding, and Washing Components. For the automotive fire-fighting systems OMAL offers the HERCULES ball valve, and for applications up to 500 bar, a valve produced in-house, and SIL3 and ATEX certified. The valve is designed for its high pressure cycles adapted with special seats for applications with non-self-lubricating fluids and used by manufacturers of skids and fire-fighting systems in various countries worldwide with excellent results. For the automotive and component production systems, there are also pneumatic valves of the co-axial series called "VIP," used mainly by OEM machine constructors or in pneumatic distribution systems, component blowing and washing systems. The floating ball valves MAGNUM (Wafer) and THOR (Flanged) and trunnion-mounted SUPREME are designed in accordance with the API 6D standard and certified SIL3, ATEX, TA LUFT fugitive emission and Fire safe to offer security where needed.

For applications in the OIL&GAS sectors, petrochemicals, refineries and lubricants, there are the ball valves FLOATING THOR and TRUNNION SUPREME, which are PED, ATEX, API6D, TA LUFT FUGITIVE EMISSION, FIRE SAFE ISO 10497 and SIL3 certified.

Valves for petrochemical, refineries and lubricating oil plants

Furthermore, OMAL upon specific requests can offer a broad range of materials like STAINLESS STEEL, DUPLEX and INCONEL and a series of seals in various realisations among which are TFM 1600, CPTFE, RPTFE, DEVLON and PEEK, thus satisfying the most diverse application needs and compatibility with the fluids. There are various construction types that vary according to the versions requested in 2 or 3 pieces and pressure classes. The sizes go from c2 to 24”, with pressure classes of ANSI 150, ANSI 300, ANSI 600, ANSI 900, ANSI 1500 and ANSI 2500. For the automation of the SUPREME models, OMAL also has HEAVY DUTY pneumatic actuators.

The chemical and pharmaceutical sectors have important implications for the type of raw material that deal in particular, with the issue of health and the environment, this is why OMAL designed and offers special valves like the Prochemie ball valves.

Valves for the chemical and pharmaceutical industry

The Prochemie ball valve was designed with care for the sector of chemicals. It is mostly used in the transformation processes of plasticizers, polymers, additives and active principles. All the metallic components of the Prochemie valves are in stainless steel: structure of 1.4408, stem of 1.4404 / 316SS and ball of 1.4408 / CF8M. The valve is available with seats in glass charged PTFE, TFM1600, PTFE + graphite or PEEK. The Prochemie ball valve is FIRE SAFE ISO 10497, API607, Fugitive Emission UNI EN ISO 15848-1 FE degree AH and TA_ Luft, PAS1085, AD2000 Merkblat, and SIL3 certified.